Embedded ID Card Laminate Film

Material: PVC

Thickness: 50-75 um

Specification: 5*5, 3*8 or customize

Application: ID cards and bank cards

Processing: Overt, covert, and forensic security features, combined with chip

Supply form: Sheet form

Product Details

PVC Card Embedded Laminate Overlay Product Description

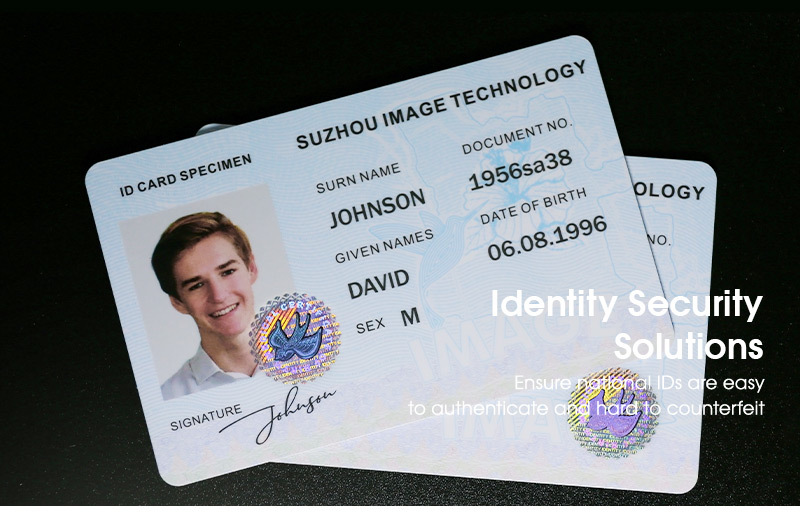

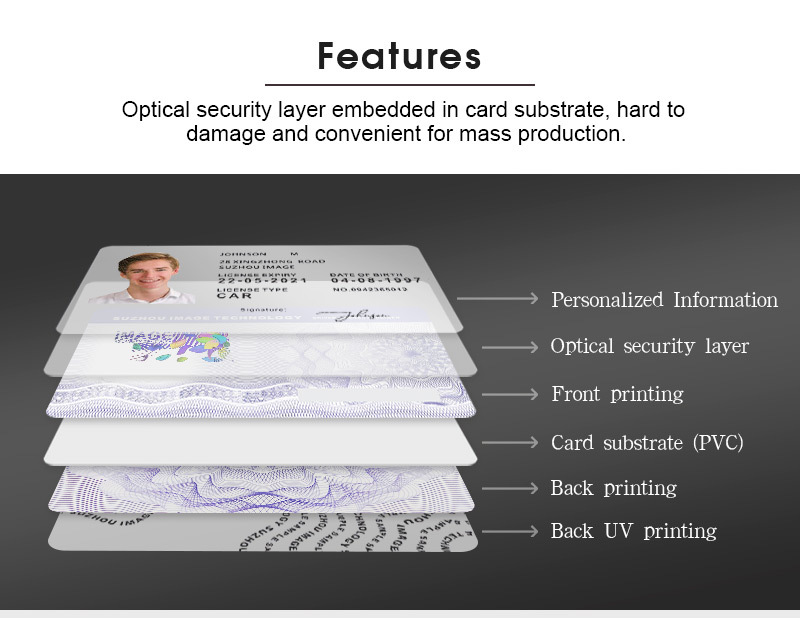

Security and durability are important for important documents that are frequently used. We recommend using IMAGE embedded laminate film. The optical security layer is embedded inside the card, protecting your ID card from counterfeiting and extending its life.

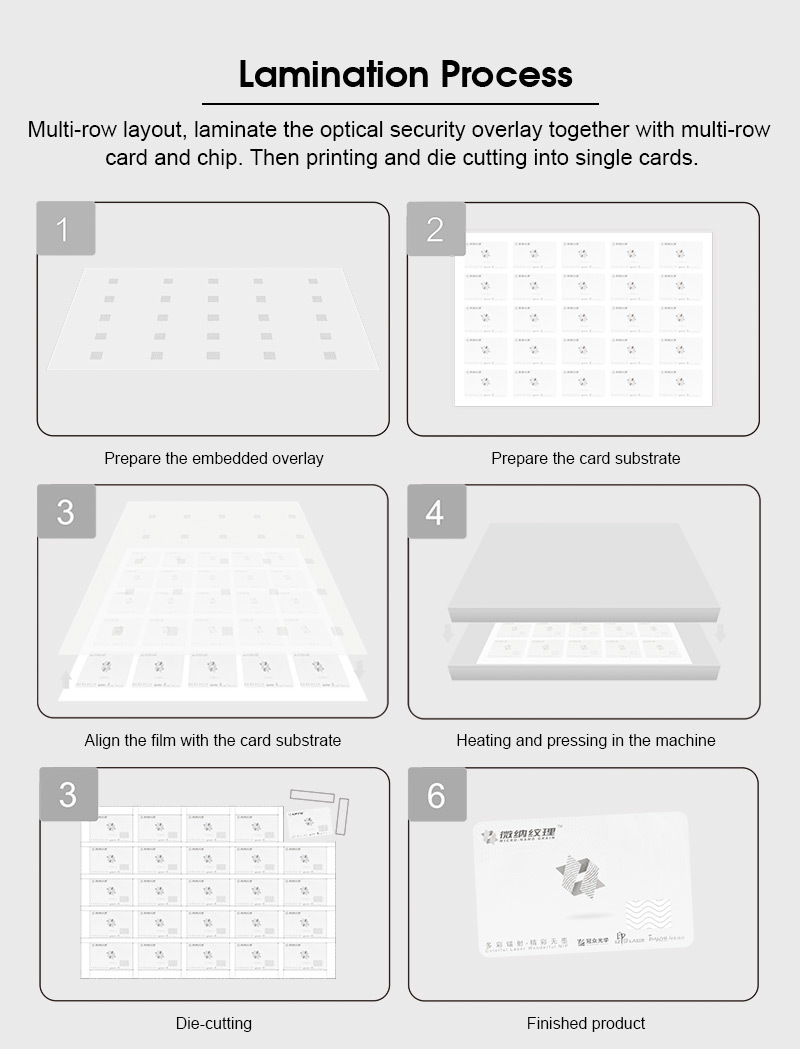

It is usually supplied to card manufacturers, who use this type of optical embedded film for mass production. The multi-line layout laminates the security pattern with multiple lines of cards and chips, which is very suitable for the security protection of ID cards, bank cards, and other plastic cards.

Specification of ID Card Laminate Film

|

Size |

Thickness |

Layout |

Packaging |

|

Customized |

50-75um |

4×8/5*5/3*8 |

100 pieces/bag 100 Sheet/Pack |

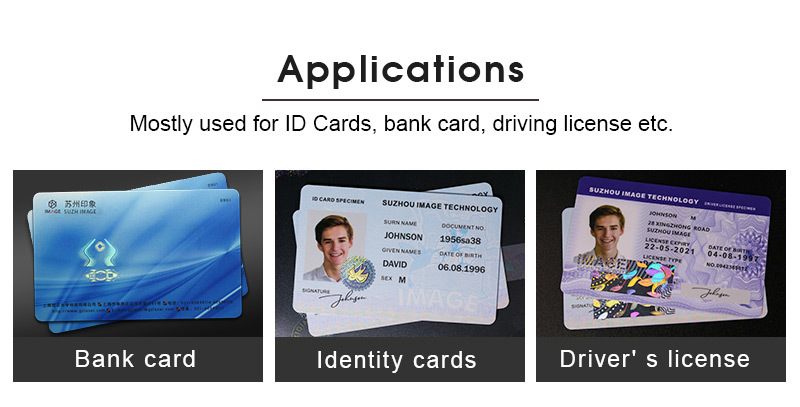

Application: Used for card type certificate lamination production. Examples: ID Card, Bank Card, social security cards, etc.

Certifying Organization: bulk production of card manufacturer.

How to use: Provide same material id card laminate film same as card body(PETG, PVC, PC) according to the card production layout, then press and lamination in the huge type lamination machine, to laminate together with card body and chip. Then printing and die cutting into single cards.

Feature: Security information is in the card body, difficult to tamper evident. Only card manufacturer can use this optical embedded laminate film.

Equipment: Bulk production lamination machine.

If you need samples, please contact our sales team, We Chat/WhatsApp: +86-18012780003.

Related Products