Book Type Heat Transfer Film

Protect Book Type Credentials from Anti-tampering

Book Type Heat Transfer Film

Protect Book Type Credentials from Anti-tampering

Reliable Book-type Transfer Overlay Factory in China

Hologram Heat Transfer Film with High Security Features

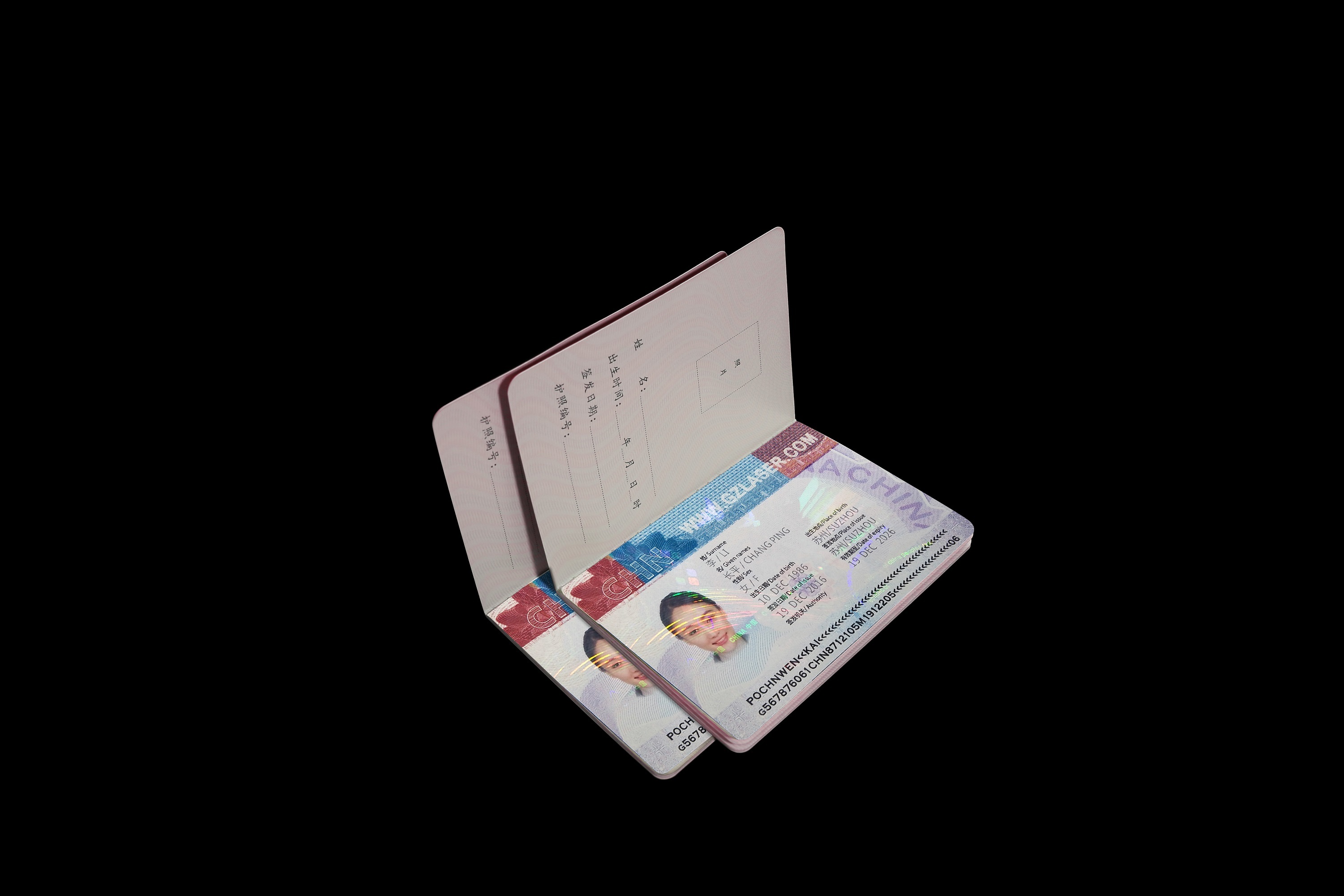

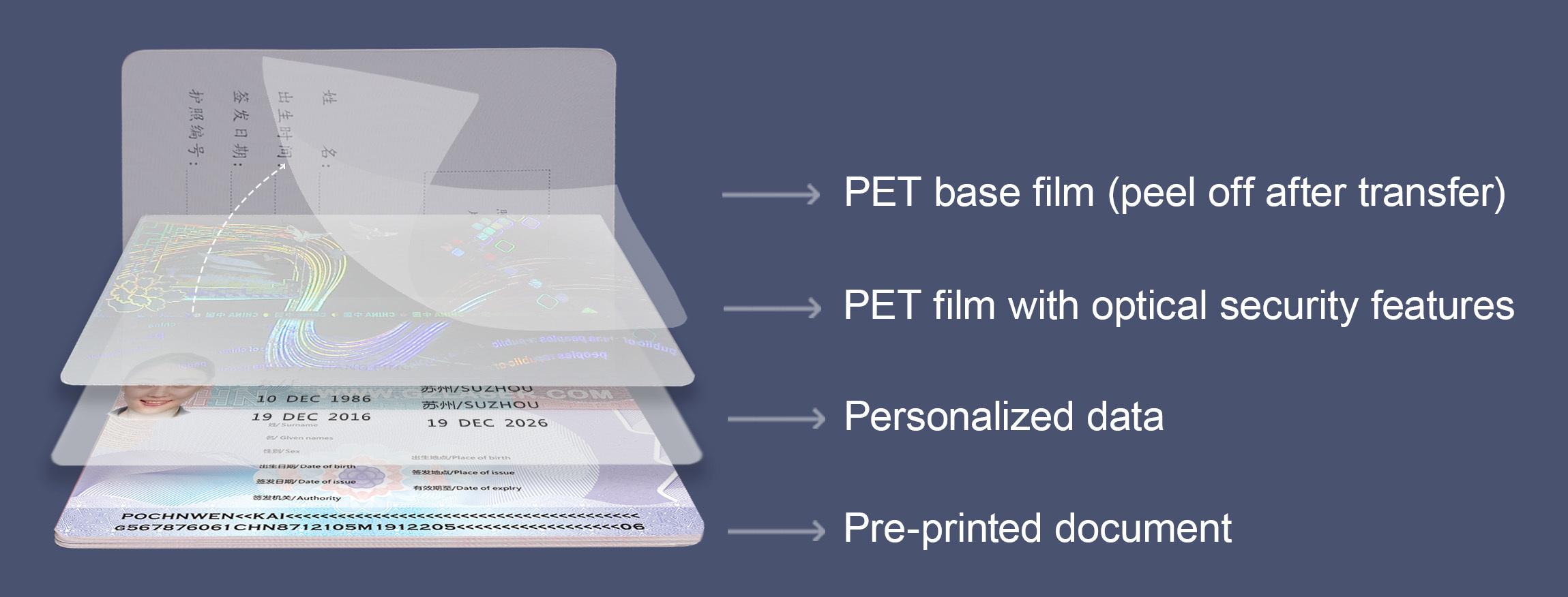

Book type heat transfer film, PET as substrate, with three levels of optical security features. One side is customized micro-nano optical security pattern, the other side (outer) with hot-melt glue. Documents and hologram heat transfer film were bonded, then PET film released, transfer hologram security pattern on documents under high temperature

Laminate optical security pattern on certificate by special equipment after personalized information printed. Online or offline laminate available. Mostly used for passport, seafarers’ certificates, etc to prevent personalized information from tampering.

Heat Transfer Film with High Security Features

Application Process

Heat transfer film in sheet form

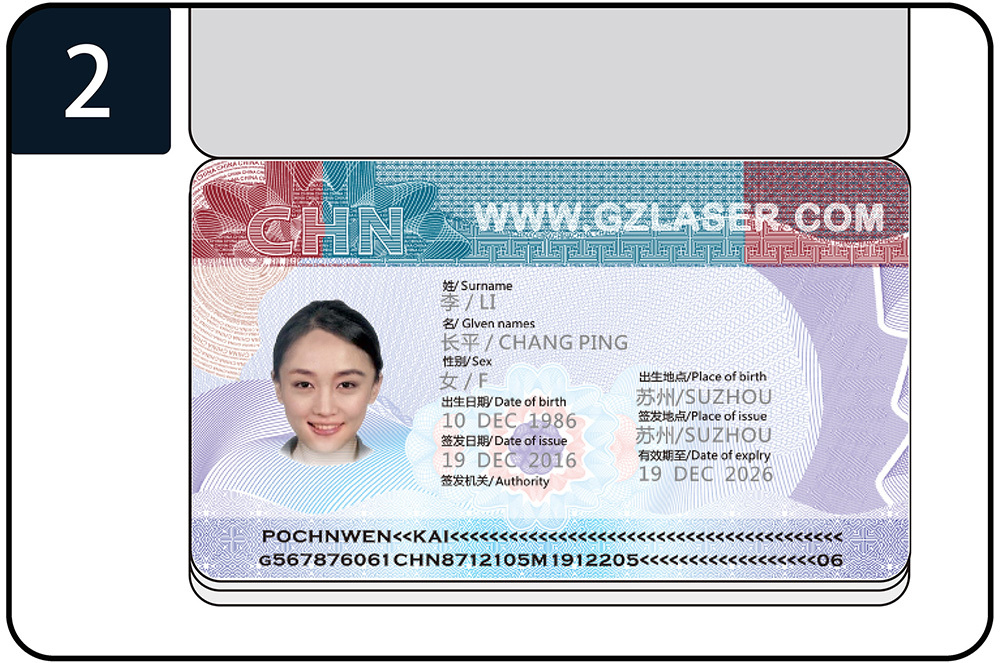

Open the personal data page

Align the security film with the data page

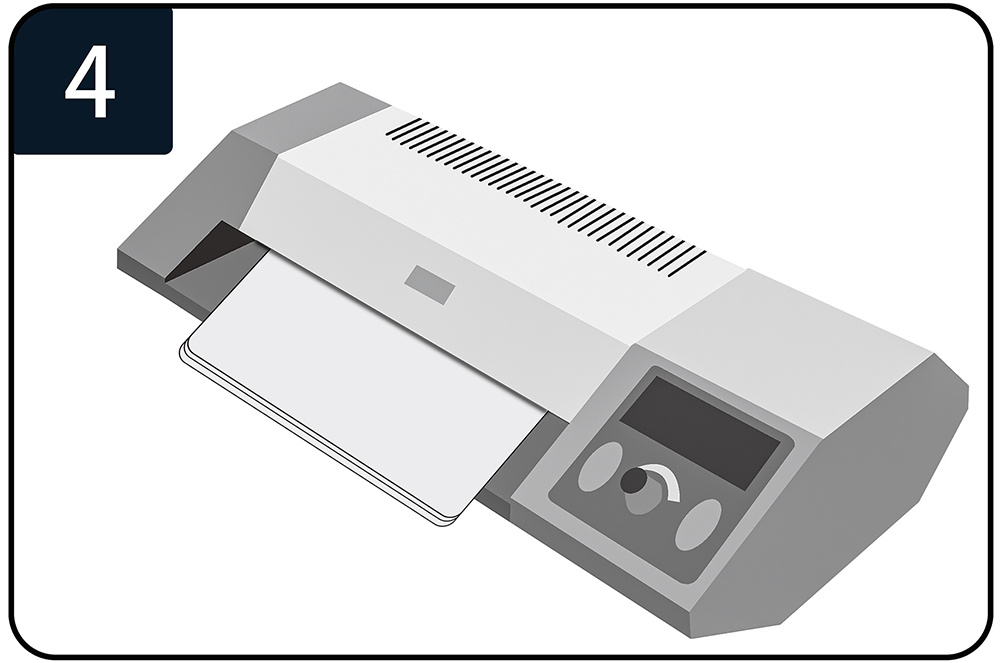

Lamination process

Clear base film peeled off

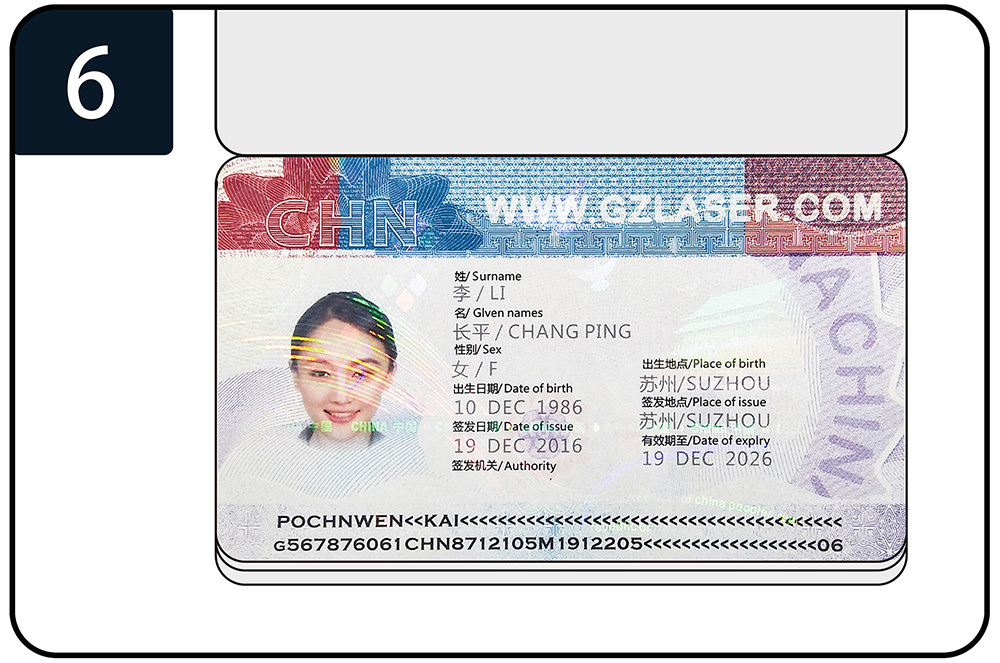

Finished product

Book Type Heat Transfer Film is Often Applied to Paper Based Documents or Certificate

The document and certificated are already processed with offset printing, gravure printing etc to enhance the document security level. The transfer overlay need to have compatible coating and gluing to achieve the perfect lamination and transferring process.

Matched with Lamination Machine

Lamination process is easy and convenient. Standard office use lamination machine is fine, but for continuous work and mass lamination, better to use industrial type lamination machine which is more stable.

TDS

Specification

Size |

Thickness |

Layout |

Packaging |

Customized |

50μm |

4×8/3×4 |

100 Sheet/Pack |

Operational environment |

PC material: Recommended laminate temperature is 180℃±2℃, lamination time 23min |

Preservation environment |

Ambient temperature 20°C - 30°C, Humidity 45%-60% |

Executive standard |

GB/T17554.1-2006 GB/T1766-2008 |

Common problem |

Layout deviation, bad fastness of security pattern. Partial area use it |

Learn more about our identity solutions!

Copyright © 2023 Suzhou Image Technology | SZIMAGETECH