Seamless Transfer Overlay

Edge to Edge Lamination to Cover the Whole id cards.

Seamless Transfer Overlay

Edge to Edge Lamination to Cover the Whole id cards.

China Seamless Transfer Overlay Production Manufacturer

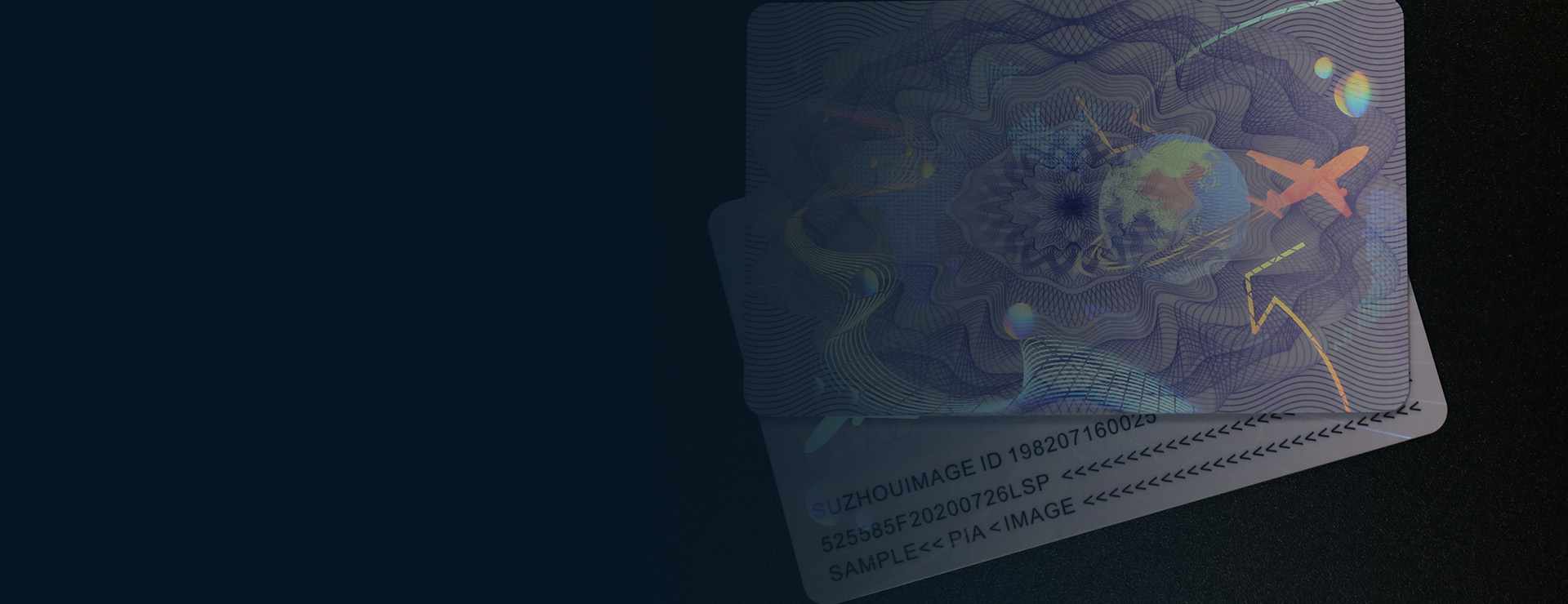

Heat Transfer Film with High Security Features

Heat transfer film is a seamless type overlay, PET thin film as carrier. After lamination, PET thin film is peeled off and only optical security layers transferred to ID card surface. The main difference compared with PATCH is that is has no thin film laminated to card, so it can be edge to edge security patterns on the ID card, better appearance. However its durability is not as good as PATCH film.

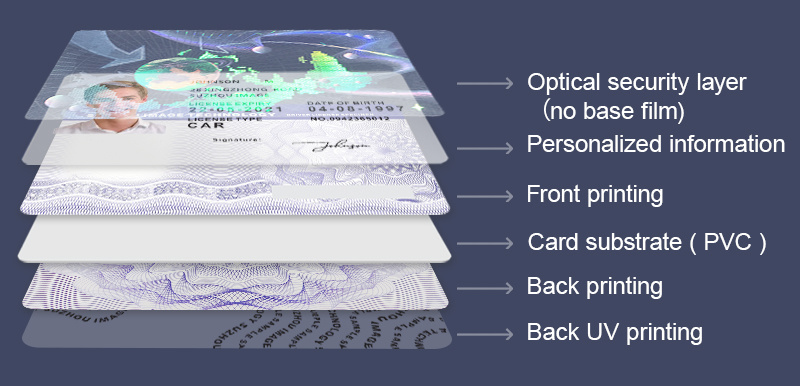

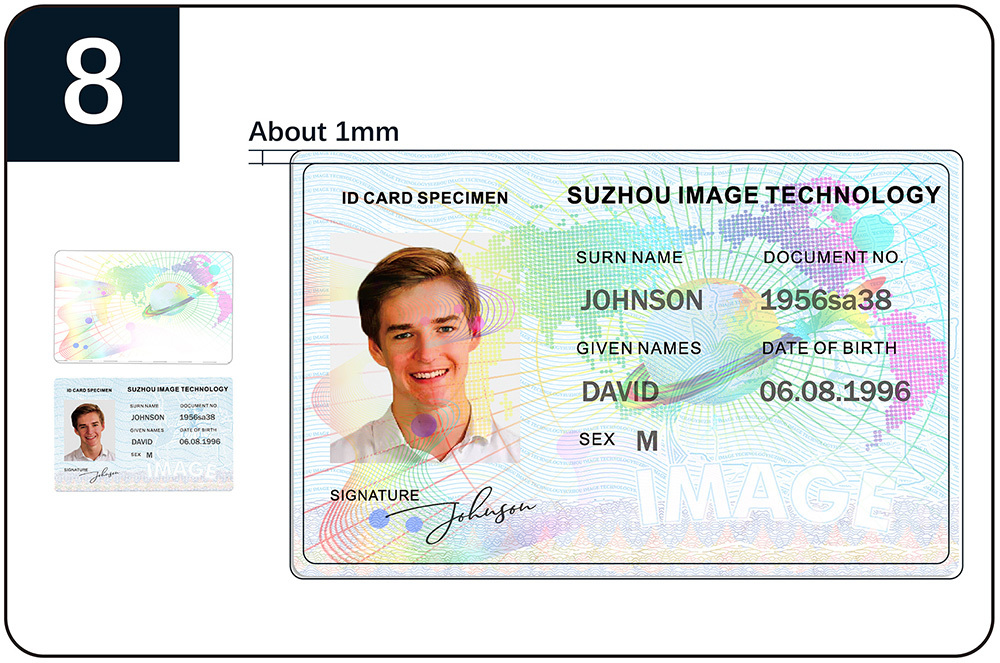

Card Structure with Seamless Transfer Overlay

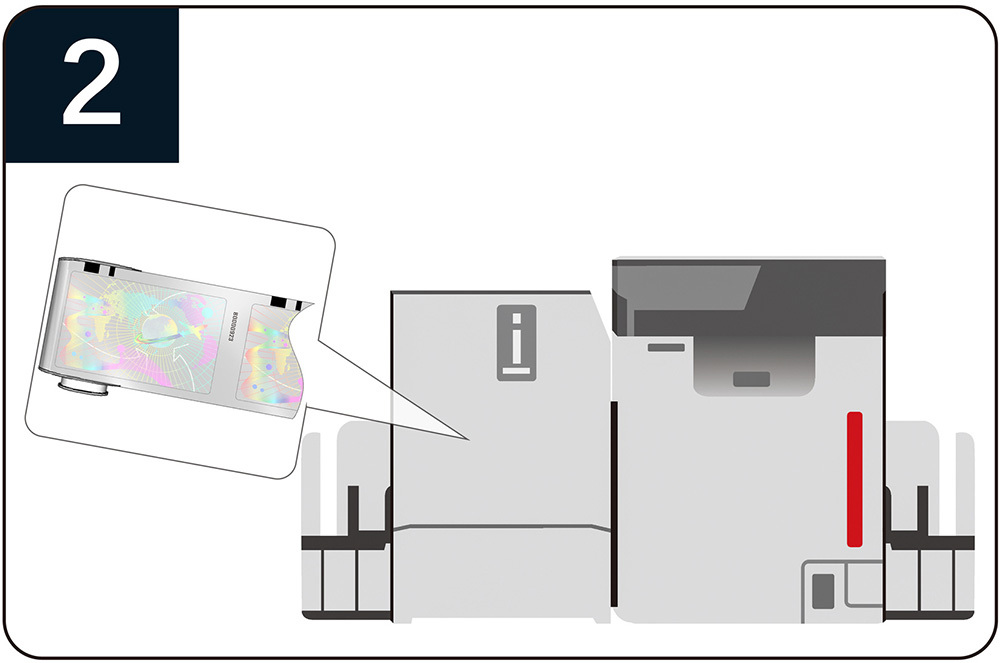

Application Process

Prepare the patch film

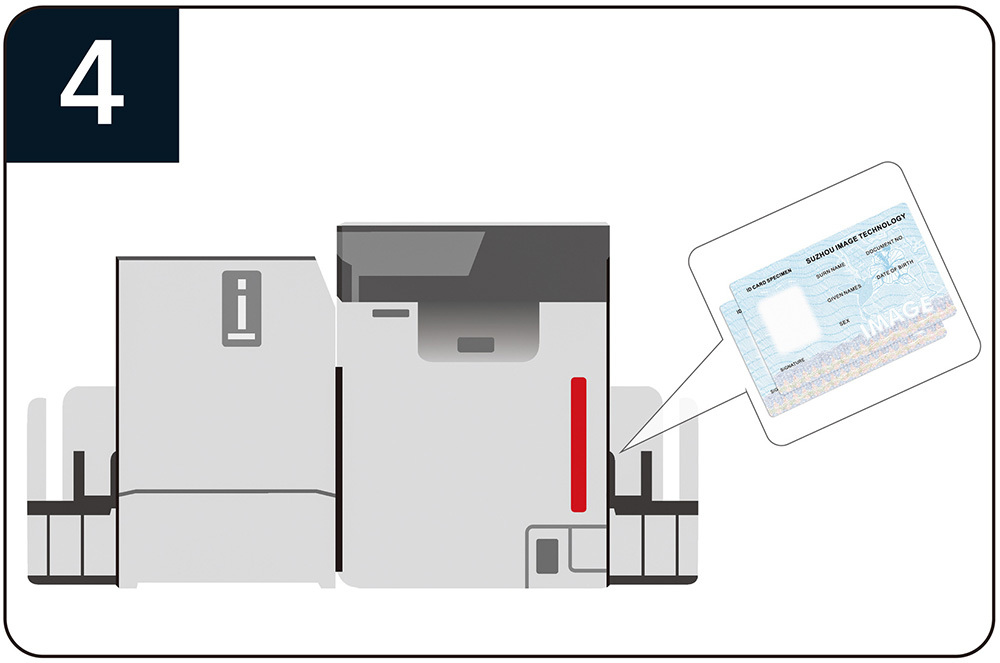

Load the film into the equipment (printing + lamination)

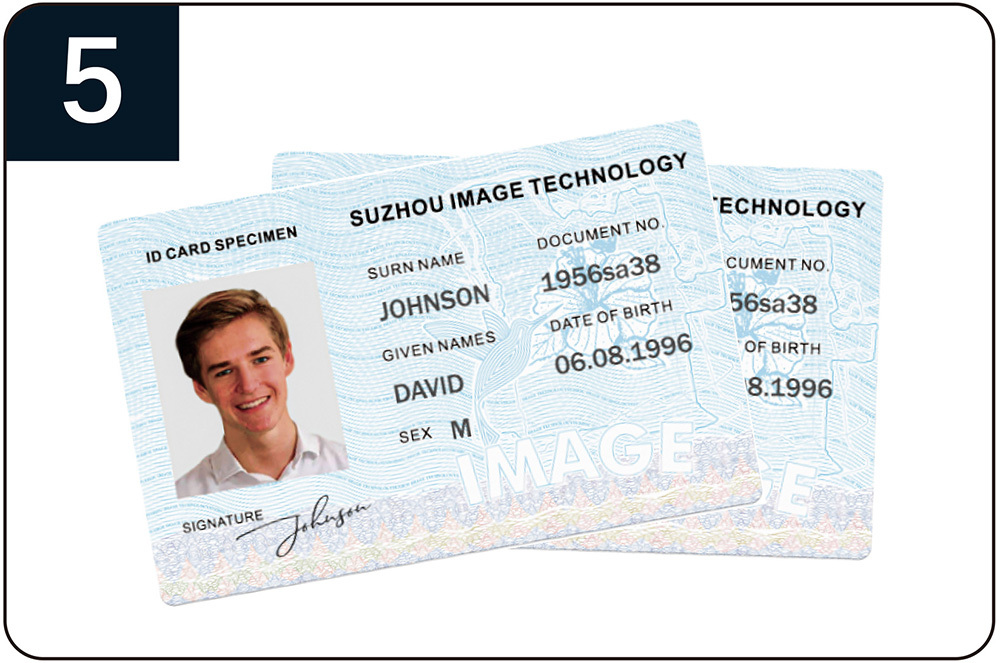

Pre-printed cards

lnput hopper

Personalized data printed

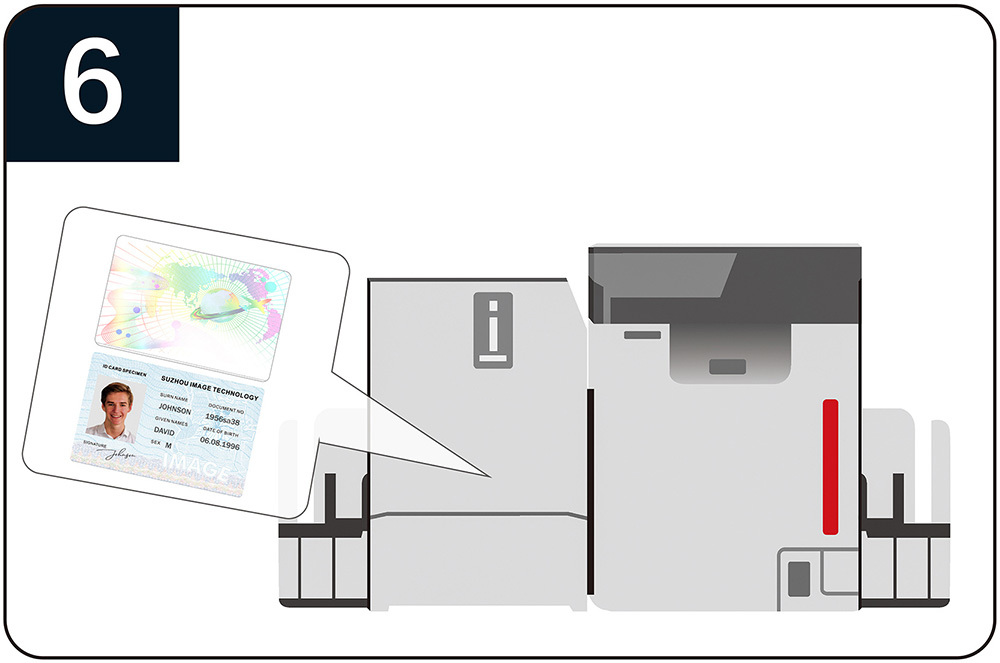

Automatically lamination

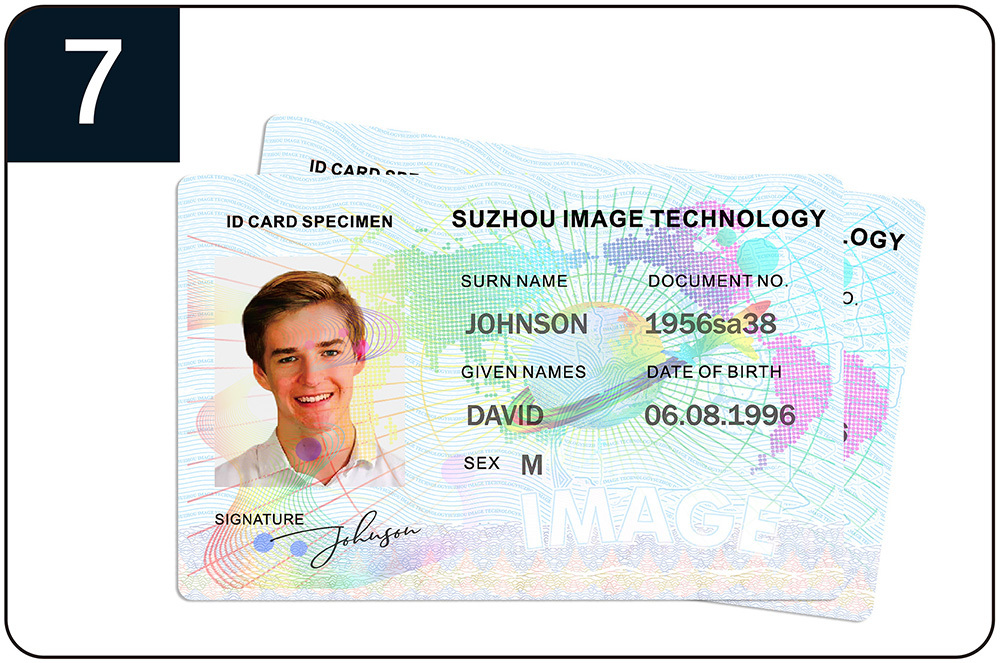

Printing and lamination finished

Edge to edge security patterns

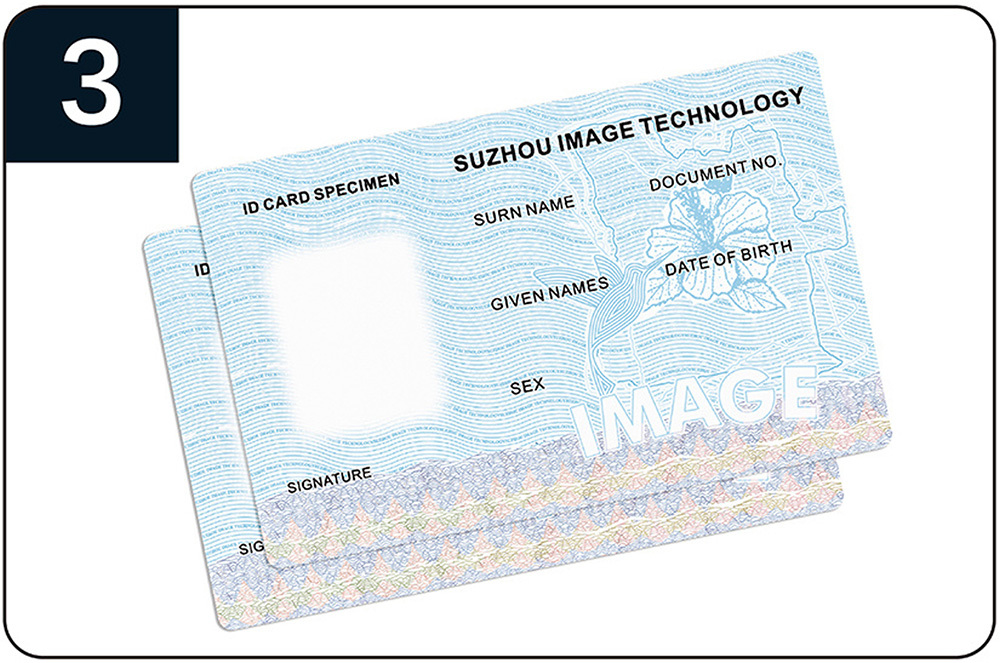

Compatible with Various Types of Card Substrates

Similar as PATCH laminate film, seamless overlay can also be applied on PVC, PETG and PC materials.

PETG Cards with Optical Security Layer

PC cards with embedded overlay

PVC cards with embedded overlay

Matched with Lamination Machine

Use specialized laminator to apply this security overlay to ID card. Suzhou Image provide complete solution, pre-printed cards, seamless transfer films, printing ribbons, printer and laminator.

TDS

Specification

Size |

Thickness |

Layout |

Packaging |

Customized |

50μm |

4×8/3×4 |

100 Sheet/Pack |

Operational environment |

PC material: Recommended laminate temperature is 180℃±2℃, lamination time 23min |

Preservation environment |

Ambient temperature 20°C - 30°C, Humidity 45%-60% |

Executive standard |

GB/T17554.1-2006 GB/T1766-2008 |

Common problem |

Layout deviation, bad fastness of security pattern. Partial area use it |

Learn more about our identity solutions!

Copyright © 2023 Suzhou Image Technology | SZIMAGETECH