High Temp Resistant Hot Stamping Foil

Verify Sensitive Documents and Certificates to Prevent Fraud.

High Temp Resistant Hot Stamping Foil

Verify Sensitive Documents and Certificates to Prevent Fraud.

Trustworthy Heat Resistant Stamping Foil Manufacturer in China

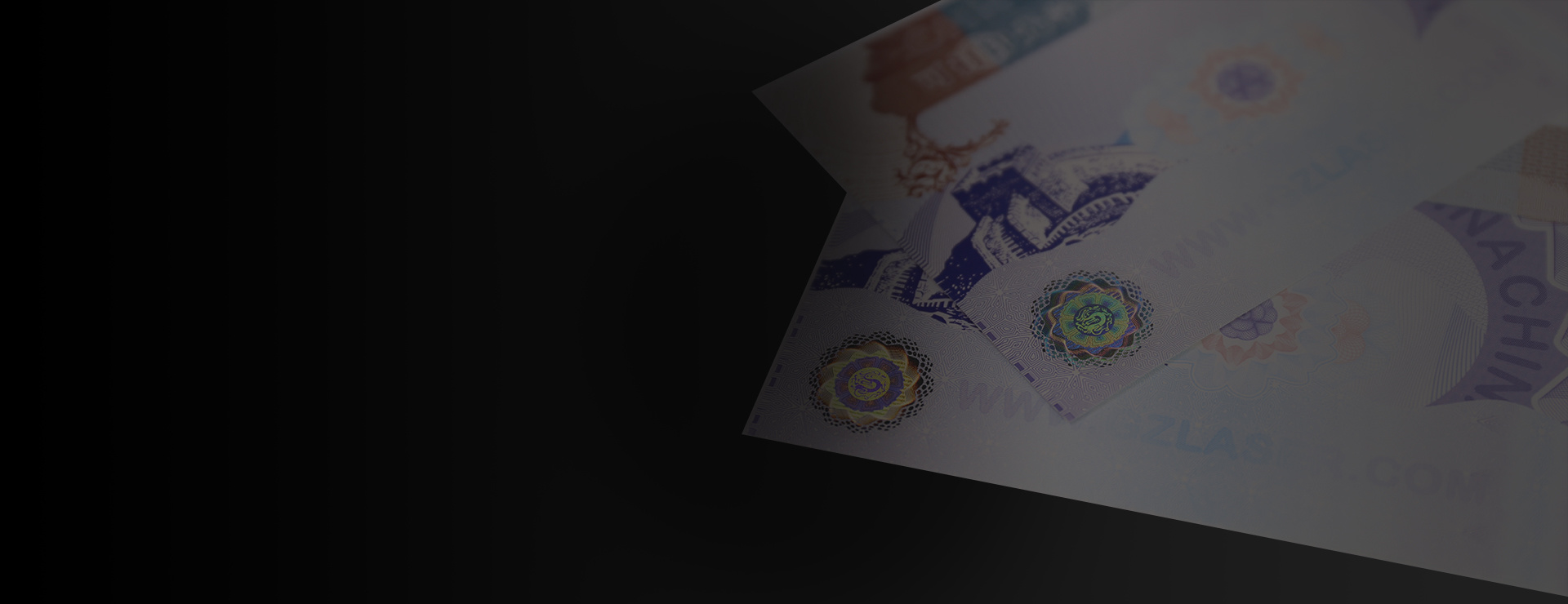

Holographic Hot Stamping Foil with High Security Features

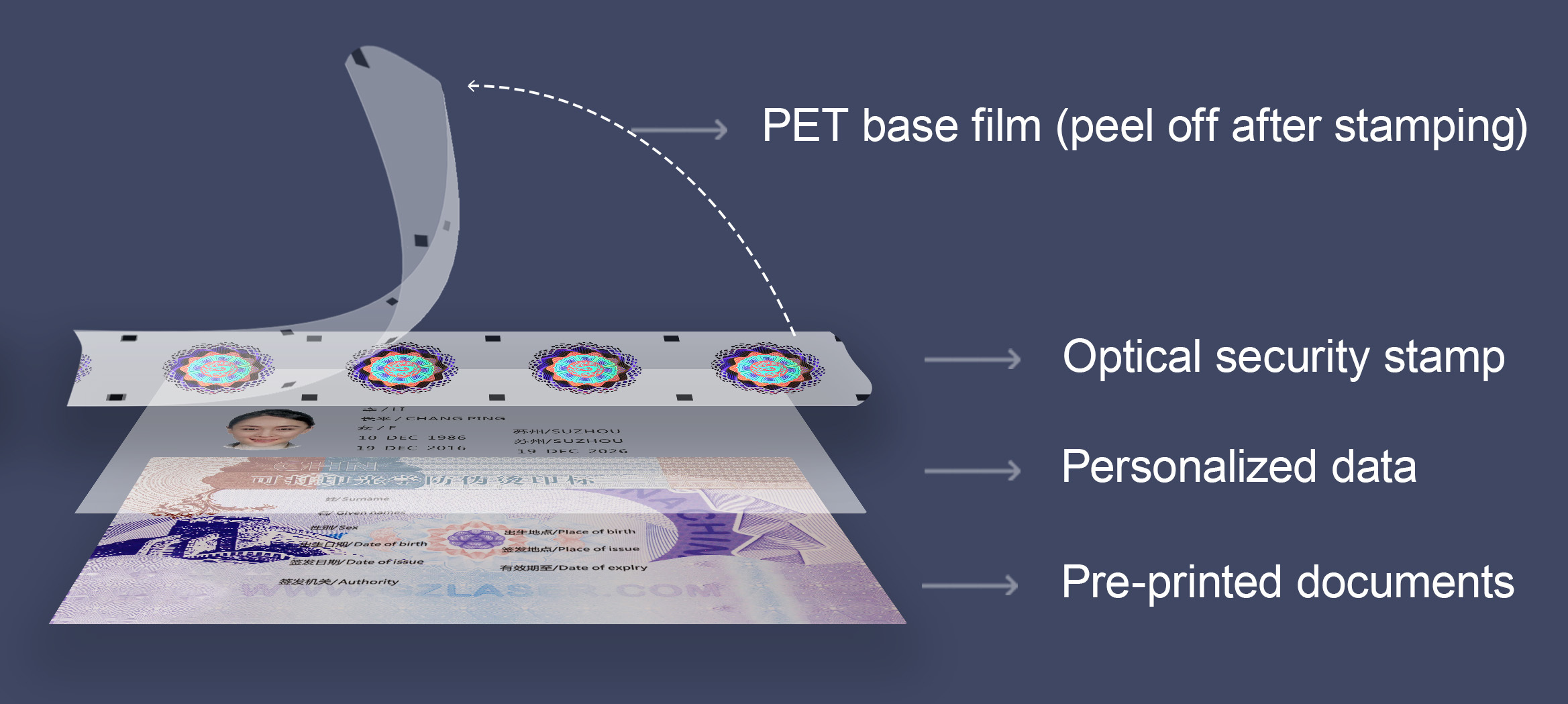

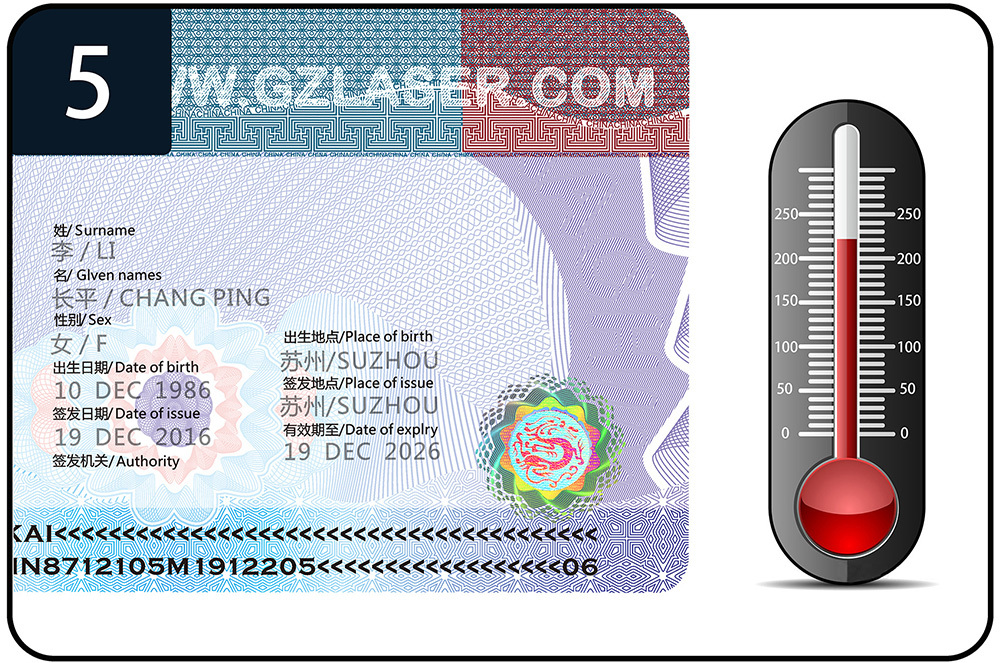

Register security hot stamping is often seen on ID cards and important documents, certificates etc. Some of them have a laser printing process after hot stamping. Therefore, it requires the stamped foil to resist high temperature as the laser printing process may reach 220℃. Suzhou Image provide the stamping foil with special coating to achieve this process. Widely used for paper documents, book type certificate, business license, passport, visa etc.

Document Structure Applied with High Temp Resistant Hot Stamping Foil

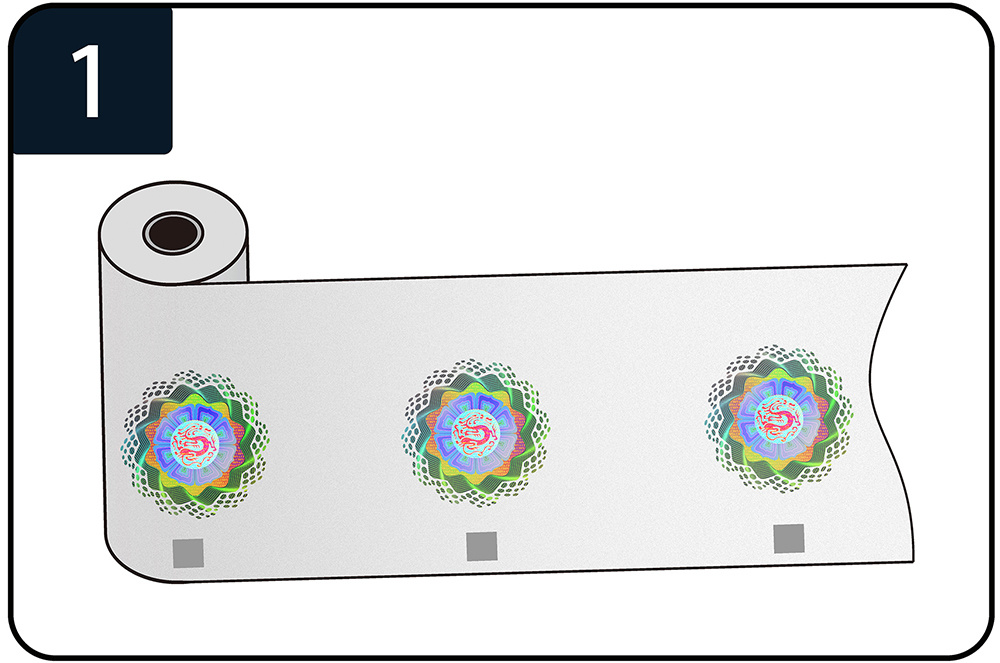

Application Process

Heat resistant hot stamping foil

Register hot stamping

Finish hot stamping

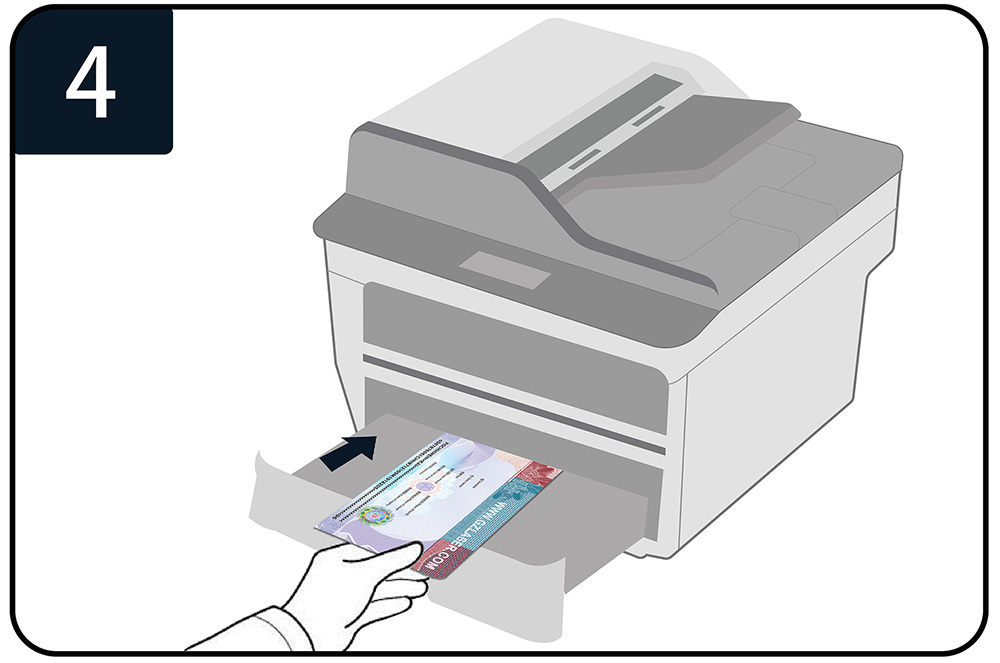

Print personalized data in laser printer

Max 220° resistance

Finished products

Paper Documents/PVC Cards with Hot Stamping Hologram Foil

High Temp Resistant Hot Stamping Foil is usually applied on VISA stickers for passport. Other security hot stamping foil can also be used for ID card with PVC and PETG substrate.

VISA Stickers for Passport

PVC ID Cards

PETG ID Cards

Standard Industrial Hot Stamping Machine

The hot stamping machine can trace the label image and accurately stamped it onto paper documents or PVC material.

TDS

Specification

Size |

Thickness |

Layout |

Packaging |

Customized |

50μm |

4×8/3×4 |

100 Sheet/Pack |

Operational environment |

PC material: Recommended laminate temperature is 180℃±2℃, lamination time 23min |

Preservation environment |

Ambient temperature 20°C - 30°C, Humidity 45%-60% |

Executive standard |

GB/T17554.1-2006 GB/T1766-2008 |

Common problem |

Layout deviation, bad fastness of security pattern. Partial area use it |

Learn more about our identity solutions!

Copyright © 2023 Suzhou Image Technology | SZIMAGETECH