Security Hologram Lamination Pouch

For Security Paper & Teslin Application

Patch Laminate Film

A Surface-applied Security Thin Film

Best Holographic Laminating Pouches Manufacturer

Hologram Laminate Pouches with High Security Features.

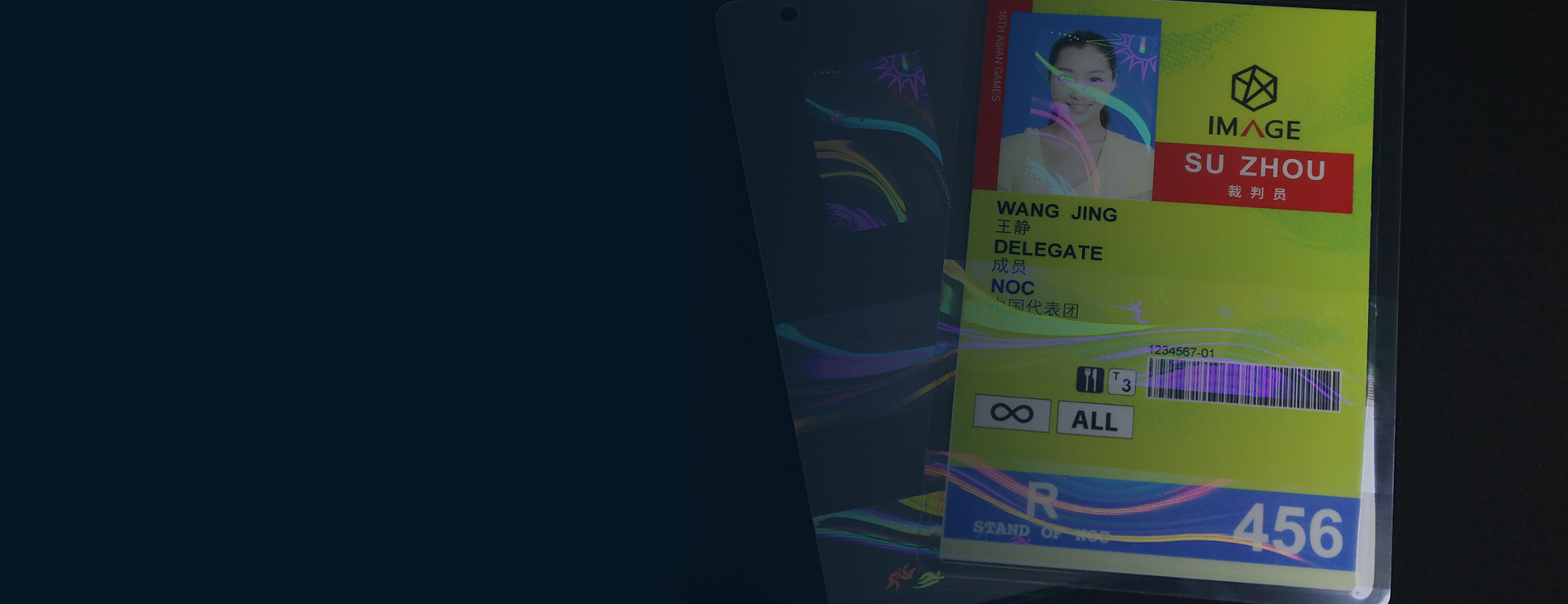

Hologram laminate pouches can be laminated with paper, Teslin, and other substrate cards to protect ID credentials from tampering. They are widely used for identification cards, driver's licenses, conference documents, pass documents, representative cards, interview cards, duty certificates, permits, business licenses, etc

Security credentials is rigid after laminated together with the hologram pouch, not easy to crack, with waterproof, moisture resistance, fading resistance, tamper resistance, long-term storage, and other advantages.

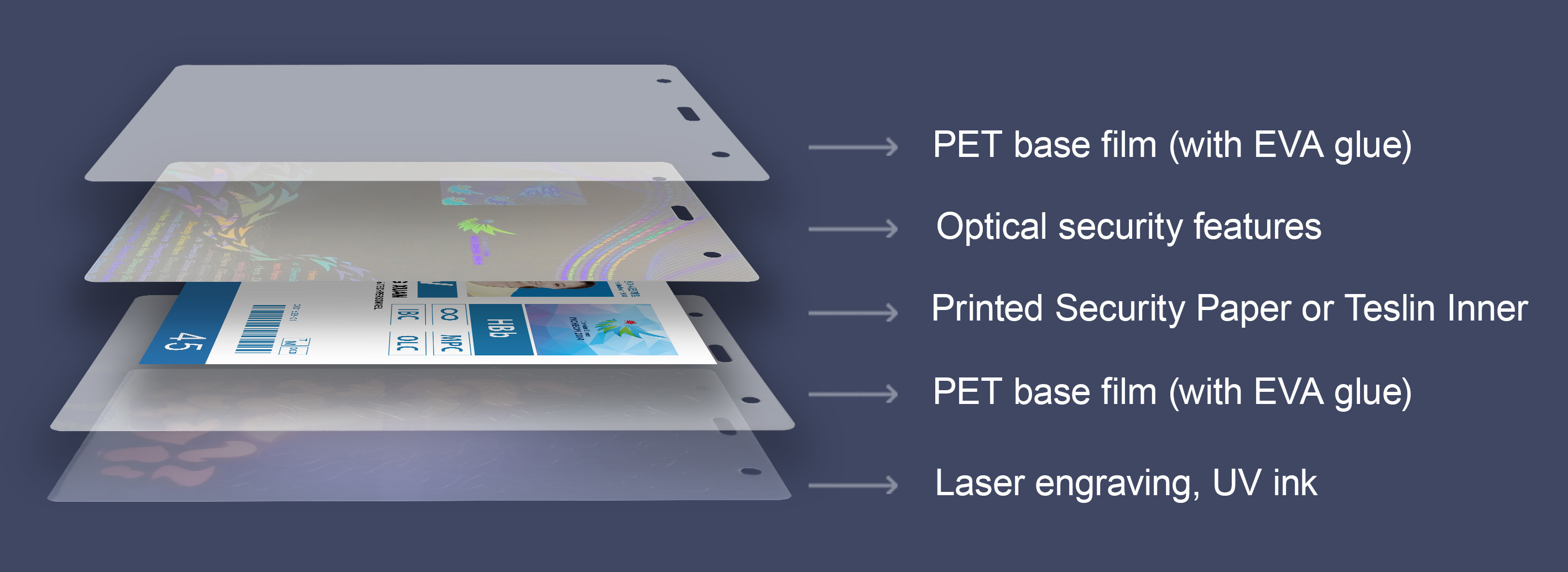

Generally, the front layer with an optical security design, good transparency, which does not affect the display of certificate information, laser engraving, and UV fluorescent security ink is optional for the back layer to enhance the security level. Meantime, it has a flexible size, a simple certification machine, and other features.

ID Card or Document Structure Applied with Laminating Pouches

Application Process

Image hologram laminated pouches can be used to event ID credentials with printed personalized information. The laminating pouch has a hologram printed on the front and the back is transparent or laser engraved.

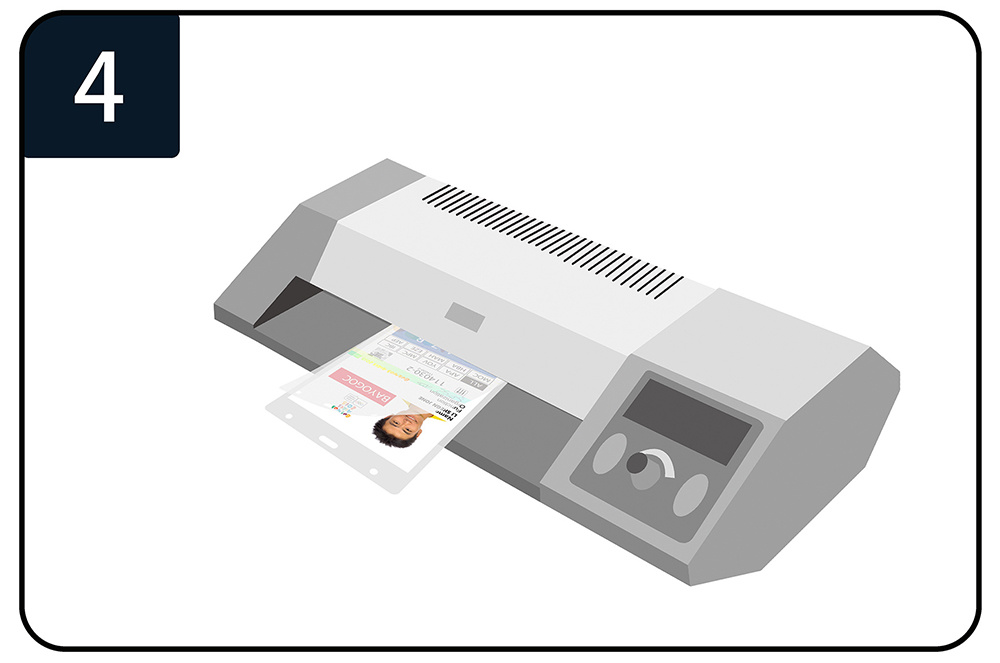

The entire laminating process is simple, all we need is a pouch laminator. The temperature is set between about 130 and 140 degrees, and the holographic lamination pouch and event credentials are laminated together. After lamination, it can protect personal information from being tampered with.

lnner paper with personalized data

Prepare the laminating pouch film

lnsert the paper into the pouch

Lamination process

Finished products

Inner Cores of Hologram Laminating Pouch Film

Compared with PATCH laminated and seamless transfer overlay, the hologram laminating pouch film has a longer history but is still the most popular security solution for ID card. And our holographic pouches are compatible with various security papers and Teslin.

Matched with Lamination Machine

Lamination process is easy and convenient. Standard office use lamination machine is fine, but for continuous work and mass lamination, better to use industrial type lamination machine which is more stable.

TDS

Specification

Size |

Thickness |

Layout |

Packaging |

Customized |

50μm |

4×8/3×4 |

100 Sheet/Pack |

Operational environment |

PC material: Recommended laminate temperature is 180℃±2℃, lamination time 23min |

Preservation environment |

Ambient temperature 20°C - 30°C, Humidity 45%-60% |

Executive standard |

GB/T17554.1-2006 GB/T1766-2008 |

Common problem |

Layout deviation, bad fastness of security pattern. Partial area use it |

Learn more about our identity solutions!

Copyright © 2023 Suzhou Image Technology | SZIMAGETECH